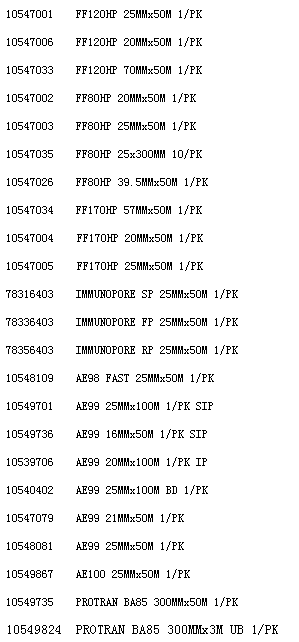

GE/whatmanNC膜 AE99孔径8um带被称25mm*50m一卷

简要描述:

GE/whatmanNC膜 AE99孔径8um带被称25mm*50m一卷,AE99 25mm x 50m 1/pkA general purpose membrane for use with most sample types that provides a good combination of sensitivity with fast wicking in a lateral

Solid. GHS product identifier Other means of identification Product type Section 1. Identification Chemical name Nitrocellulose Relevant identified uses of the substance or mixture and uses advised against Identified uses Not applicable. Uses advised against Reason GE Healthcare SAFETY DATA SHEET AE99 Membrane, Cellulose nitrate, 25 mm x 50 m Catalogue Number 10548081 9010548081 Singapore Supplier GE Healthcare UK Ltd Amersham Place Little Chalfont Buckinghamshire HP7 9NA England GE Healthcare Pte Ltd. 1 Maritime Square #13-01 HarbourFront Center Singapore 099253 Emergency ephone number (with hours of operation) +65 6773 7303 (hours of operation: 8.30 pm – 5.30 pm) Confirms to Singapore standard SS 586 : part 3 : 2008 Use in laboratories Section 2. Hazards identification Classification of the substance or FLAMMABLE SOLIDS – Category 2 mixture Signal word Warning Hazard statements Flammable solid. Hazard pictograms Precautionary statements Prevention Wear protective gloves. Wear eye or face protection. Keep away from heat, sparks, open flames and hot surfaces. – No smoking. Response Not applicable. Storage Not applicable. Disposal Not applicable. Other hazards which do not result in classification None known. GHS label elements Validation date : 21 January 2016 Version 3 Article Number Page: 1/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Section 3. Composition/information on ingredients Nitrocellulose 100 9004-70-0 Ingredient name % CAS number There are no additional ingredients present which, within the current knowledge of the supplier and in the concentrations applicable, are classified as hazardous to health or the environment and hence require reporting in this section. Chemical name Nitrocellulose Other means of identification CAS number 9004-70-0 Substance/mixture Product code 10548081 CAS number/other identifiers EC number Not available. Occupational exposure limits, if available, are listed in Section 8. Substance Chemical formula HNO3.xUnspecified No special recommendations. In case of contact with eyes, rinse immediay with plenty of water. Get medical attention if irritation occurs. Wash with soap and water. Get medical attention if irritation develops. No special recommendations. Section 4. First aid measures Eye contact Skin contact Inhalation Ingestion Protection of first-aiders No action shall be taken involving any personal risk or without suitable training. It may be dangerous to the person providing aid to give mouth-to-mouth resuscitation. Notes to physician In case of inhalation of decomposition products in a fire, symptoms may be delayed. The exposed person may need to be kept under medical surveillance for 48 hours. Description of necessary first aid measures Specific treatments No specific treatment. Most important symptoms/effects, acute and delayed Inhalation Exposure to decomposition products may cause a health hazard. Serious effects may be delayed following exposure. Ingestion No known significant effects or critical hazards. Skin contact No known significant effects or critical hazards. Eye contact No known significant effects or critical hazards. Over-exposure signs/symptoms Skin contact Ingestion Inhalation No specific data. No specific data. No specific data. Eye contact No specific data. Potential acute health effects See toxicological information (Section 11) Indication of immediate medical attention and special treatment needed, if necessary Section 5. Fire-fighting measures Promptly isolate the scene by removing all persons from the vicinity of the incident if there is a fire. No action shall be taken involving any personal risk or without suitable training. Move containers from fire area if this can be done without risk. Use water spray to keep fire-exposed containers cool. Hazardous thermal decomposition products Specific hazards arising from the chemical Decomposition products may include the following materials: nitrogen oxides Flammable solid. Use dry chemical, CO?, water spray (fog) or foam. Extinguishing media Do not use water jet. Suitable extinguishing media Unsuitable extinguishing media Special protective actions for firefighters Validation date : 21 January 2016 Version 3 Article Number Page: 2/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Fire-fighters should wear appropriate protective equipment and self-contained breathing apparatus (SCBA) with a full face-piece operated in positive pressure mode. Special protective equipment for fire-fighters Section 6. Accidental release measures Environmental precautions Personal precautions, protective equipment and emergency procedures Eliminate all ignition sources. Vacuum or sweep up material and place in a designated, labeled waste container. No action shall be taken involving any personal risk or without suitable training. Evacuate surrounding areas. Keep unnecessary and unprotected personnel from entering. Do not touch or walk through spilled material. Shut off all ignition sources. No flares, smoking or flames in hazard area. Provide adequate ventilation. Wear appropriate respirator when ventilation is inadequate. Put on appropriate personal protective equipment. No special recommendations. Large spill Eliminate all ignition sources. Vacuum or sweep up material and place in a designated, labeled waste container. Small spill Methods and materials for containment and cleaning up For non-emergency personnel For emergency responders If specialised clothing is required to deal with the spillage, take note of any information in Section 8 on suitable and unsuitable materials. See also the information in “For non-emergency personnel”. Section 7. Handling and storage Conditions for safe storage, including any incompatibilities Eating, drinking and smoking should be prohibited in areas where this material is handled, stored and processed. Workers should wash hands and face before eating, drinking and smoking. Remove contaminated clothing and protective equipment before entering eating areas. See also Section 8 for additional information on hygiene measures. Store between the following temperatures: 18 to 25°C (64.4 to 77°F). Store in accordance with local regulations. Store in a segregated and approved area. Store in original container protected from direct sunlight in a dry, cool and well-ventilated area, away from incompatible materials (see Section 10) and food and drink. Eliminate all ignition sources. Separate from oxidizing materials. Keep container tightly closed and sealed until ready for use. Containers that have been opened must be carefully resealed and kept upright to prevent leakage. Do not store in unlabeled containers. Use appropriate containment to avoid environmental contamination. Precautions for safe handling Protective measures Put on appropriate personal protective equipment (see Section 8). Do not ingest. Avoid contact with eyes, skin and clothing. Use only with adequate ventilation. Wear appropriate respirator when ventilation is inadequate. Do not enter storage areas and confined spaces unless adequay ventilated. Keep in the original container or an approved alternative made from a compatible material, kept tightly closed when not in use. Store and use away from heat, sparks, open flame or any other ignition source. Use only non-sparking tools. Empty containers retain product residue and can be hazardous. Do not reuse container. Advice on general occupational hygiene None. Section 8. Exposure controls/personal protection Hand protection Chemical-resistant, impervious gloves complying with an approved standard should be worn at all times when handling chemical products if a risk assessment indicates this is necessary. Considering the parameters specified by the glove manufacturer, check during use that the gloves are still retaining their protective properties. It should be noted that the time to breakthrough for any glove material may be different for different glove manufacturers. In the case of mixtures, consisting of several substances, the protection time of the gloves cannot be accuray estimated. Safety eyewear complying with an approved standard should be used when a risk assessment indicates this is necessary to avoid exposure to liquid splashes, mists, gases or dusts. If contact is possible, the following protection should be worn, unless the assessment indicates a higher degree of protection: safety glasses with side-shields. Eye/face protection Environmental exposure controls No special recommendations. Appropriate engineering controls No special ventilation requirements. Wash hands, forearms and face thoroughly after handling chemical products, before eating, smoking and using the lavatory and at the end of the working period. Appropriate techniques should be used to remove potentially contaminated clothing. Wash contaminated clothing before reusing. Ensure that eyewash stations and safety showers are close to the workstation location. Hygiene measures Control parameters Individual protection measures Occupational exposure limits Skin protection Validation date : 21 January 2016 Version 3 Article Number Page: 3/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Respiratory protection A respirator is not needed under normal and intended conditions of product use. Body protection Personal protective equipment for the body should be selected based on the task being performed and the risks involved and should be approved by a specialist before handling this product. When there is a risk of ignition from static electricity, wear anti-static protective clothing. For the greatest protection from static discharges, clothing should include anti-static overalls, boots and gloves. Other skin protection Appropriate footwear and any additional skin protection measures should be selected based on the task being performed and the risks involved and should be approved by a specialist before handling this product. Section 9. Physical and chemical properties Physical state Melting point Vapor pressure Relative density Vapor density Solubility Solid. Not available. Not available. Not available. 0 kPa (0 mm Hg) [room temperature] Partially soluble in the following materials: methanol, diethyl ether and acetone. Insoluble in the following materials: cold water and hot water. Odor Odorless. pH Color White. Evaporation rate Not available. Auto-ignition temperature Flash point >160°C (>320°F) Closed cup: 12.85°C (55.1°F) Not available. Not applicable. Viscosity Dynamic (room temperature): Not applicable. Kinematic (room temperature): Not applicable. Odor threshold Not available. Partition coefficient: n-octanol/ water Appearance Boiling point Not available. Flammability (solid, gas) Product becomes a 'Flammable Solid category 2' after removing the membrane from the package. If the product is still in it's original packaging it is not a 'Flammable Solid category 2'. Lower and upper explosive (flammable) limits Not available. Burning rate Not available. Burning time Not available. SADT Not available. Decomposition temperature Not available. Solubility in water Not applicable. Section 10. Stability and reactivity Hazardous decomposition products Conditions to avoid Avoid all possible sources of ignition (spark or flame). Under normal conditions of storage and use, hazardous decomposition products should not be produced. Chemical stability The product is stable. Reactive or incompatible with the following materials: oxidizing materials Incompatible materials Possibility of hazardous reactions Under normal conditions of storage and use, hazardous reactions will not occur. Reactivity No specific test data related to reactivity available for this product or its ingredients. SADT Not available. Validation date : 21 January 2016 Version 3 Article Number Page: 4/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Section 11. Toxicological information Acute toxicity Nitrocellulose LD50 Oral Rat >5 g/kg – Product/ingredient name Result Species Dose Exposure Conclusion/Summary Not toxic. Not available. Conclusion/Summary Not toxic. Carcinogenicity Not available. Mutagenicity Not available. Teratogenicity Not available. Reproductive toxicity Not available. Irritation/Corrosion Not available. Sensitization Not available. Information on the likely routes of exposure Inhalation Exposure to decomposition products may cause a health hazard. Serious effects may be delayed following exposure. Ingestion No known significant effects or critical hazards. Skin contact No known significant effects or critical hazards. Eye contact No known significant effects or critical hazards. General No known significant effects or critical hazards. Carcinogenicity No known significant effects or critical hazards. Symptoms related to the physical, chemical and toxicological characteristics Skin contact Ingestion Inhalation No specific data. No specific data. No specific data. Eye contact No specific data. Potential chronic health effects Delayed and immediate effects and also chronic effects from short and long term exposure Specific target organ toxicity (single exposure) Specific target organ toxicity (repeated exposure) Not available. Not available. Aspiration hazard Not available. Information on toxicological effects Routes of entry not anticipated: Oral, Dermal, Inhalation. Potential acute health effects Potential immediate effects Not available. Short term exposure Potential delayed effects Not available. Potential immediate effects Not available. Long term exposure Potential delayed effects Not available. Validation date : 21 January 2016 Version 3 Article Number Page: 5/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Mutagenicity No known significant effects or critical hazards. Teratogenicity No known significant effects or critical hazards. Developmental effects No known significant effects or critical hazards. Fertility effects No known significant effects or critical hazards. Numerical measures of toxicity Not available. Acute toxicity estimates Section 12. Ecological information Bioaccumulative potential Other adverse effects No known significant effects or critical hazards. Not available. Toxicity Nitrocellulose Acute EC50 579000 µg/l Fresh water Algae – Pseudokirchneriella subcapitata 96 hours Product/ingredient name Result Species Exposure Conclusion/Summary No known significant effects or critical hazards. Persistence/degradability Soil/water partition coefficient (KOC) Not available. Mobility in soil Not available. Section 13. Disposal considerations The generation of waste should be avoided or minimized wherever possible. Disposal of this product, solutions and any by-products should at all times comply with the requirements of environmental protection and waste disposal legislation and any regional local authority requirements. Dispose of surplus and non-recyclable products via a licensed waste disposal contractor. Waste should not be disposed of untreated to the sewer unless fully compliant with the requirements of all authorities with jurisdiction. Waste packaging should be recycled. Incineration or landfill should only be considered when recycling is not feasible. This material and its container must be disposed of in a safe way. Care should be taken when handling emptied containers that have not been cleaned or rinsed out. Empty containers or liners may retain some product residues. Avoid dispersal of spilled material and runoff and contact with soil, waterways, drains and sewers. Disposal methods Section 14. Transport information UN number – – – – – – – Not regulated. – – Not regulated. Not regulated. Remarks Product is not regulated as Dangerous Goods for transport according to a expert opinion by BAM (Bundesanstalt für Materialforschung and -prüfung) with number 2.2-91/15-E on 12 May 2015. “The above named nitrocellulose membrane filters (in form of round filters, pre-cut parts and curved parts) do not fulfill the criteria of Class 1 'Explosives' and the division 4.1 'Flammable Solids' Remarks The product is not regulated as Dangerous Goods for transport according to a expert opinion by BAM (Bundesanstalt für Materialforschung and -prüfung) with number 2. 2-91/15-E on 12 May 2015. “The above named nitrocellulose membrane filters (in form of round filters, pre-cut parts and curved parts) do not fulfill the criteria of Class 1 'Explosives' and the division 4.1 'Flammable Solids' Remarks The product is not regulated as Dangerous Goods for transport according to a expert opinion by BAM (Bundesanstalt für Materialforschung and -prüfung) with number 2.2-91/15-E on 12 May 2015. “The above named nitrocellulose membrane filters (in form of round filters, pre-cut parts and curved parts) do not fulfill the criteria of Class 1 'Explosives' and the division 4.1 'Flammable Solids' UN IMDG IATA UN proper shipping name Transport hazard class(es) Packing group Additional information Environmental hazards No. No. No. Validation date : 21 January 2016 Version 3 Article Number Page: 6/7 28417383 9528417383 AE99 Membrane, Cellulose nitrate, 25 mm x 50 m 10548081 Transport in bulk according to Annex II of MARPOL 73/78 and the IBC Code Not available. of RID/ADR (GGVSE), IMDG-Code (GGVSee) and the ICAO-Technical Instructions.” of RID/ADR (GGVSE), IMDG-Code (GGVSee) and the ICAO-Technical Instructions.” of RID/ADR (GGVSE), IMDG-Code (GGVSee) and the ICAO-Technical Instructions.” Special precautions for user Transport within user’s premises: always transport in closed containers that are upright and secure. Ensure that persons transporting the product know what to do in the event of an accident or spillage. Section 15. Regulatory information Singapore – hazardous chemicals under government control None. Section 16. Other information History Date of printing Date of issue/Date of revision Version To the best of our knowledge, the information contained herein is accurate. However, neither the above-named supplier, nor any of its subsidiaries, assumes any liability whatsoever for the accuracy or completeness of the information contained herein. Final determination of suitability of any material is the sole responsibility of the user. All materials may present unknown hazards and should be used with caution. Although certain hazards are described herein, we cannot guarantee that these are the only hazards that exist. Notice to reader Date of previous issue Indicates information that has changed from previously issued version. References Not available. Key to abbreviations ADN = European Provisions concerning the International Carriage of Dangerous Goods by Inland Waterway ADR = The European Agreement concerning the International Carriage of Dangerous Goods by Road ATE = Acute Toxicity Estimate BCF = Bioconcentration Factor GHS = Globally Harmonized System of Classification and Labelling of Chemicals IATA = International Air Transport Association IBC = Intermediate Bulk Container IMDG = International Maritime Dangerous Goods LogPow = logarithm of the octanol/water partition coefficient MARPOL 73/78 = International Convention for the Prevention of Pollution From Ships, 1973 as modified by the Protocol of 1978. (“Marpol” = marine pollution) RID = The Regulations concerning the International Carriage of Dangerous Goods by Rail UN = United Nations 27 November 2014. 3 26 January 2016 21 January 2016 Validation date : 21 January 2016 Version 3 Article Number Page: 7/7 28417383 9528417383